Project Scope

BMWC’s partnership with this Midwest refinery client spans over 30 years and includes maintenance, capital, and turnaround construction management and execution services. When BMWC’s client invested more than $5 billion into their refinery to modernize their operations, they entrusted BMWC with executing the most significant turnaround associated with the modernization project, a $200M crude unit turnaround.

BMWC and their support contractors established an Integrated Project Management Team to execute the crude unit turnaround. Led by BMWC, the integrated team provided general project management, project controls, accounting, and field supervision support. BMWC also self-performed all heavy craft scopes of work, including boilermaker, pipefitter, ironworker, and millwright.

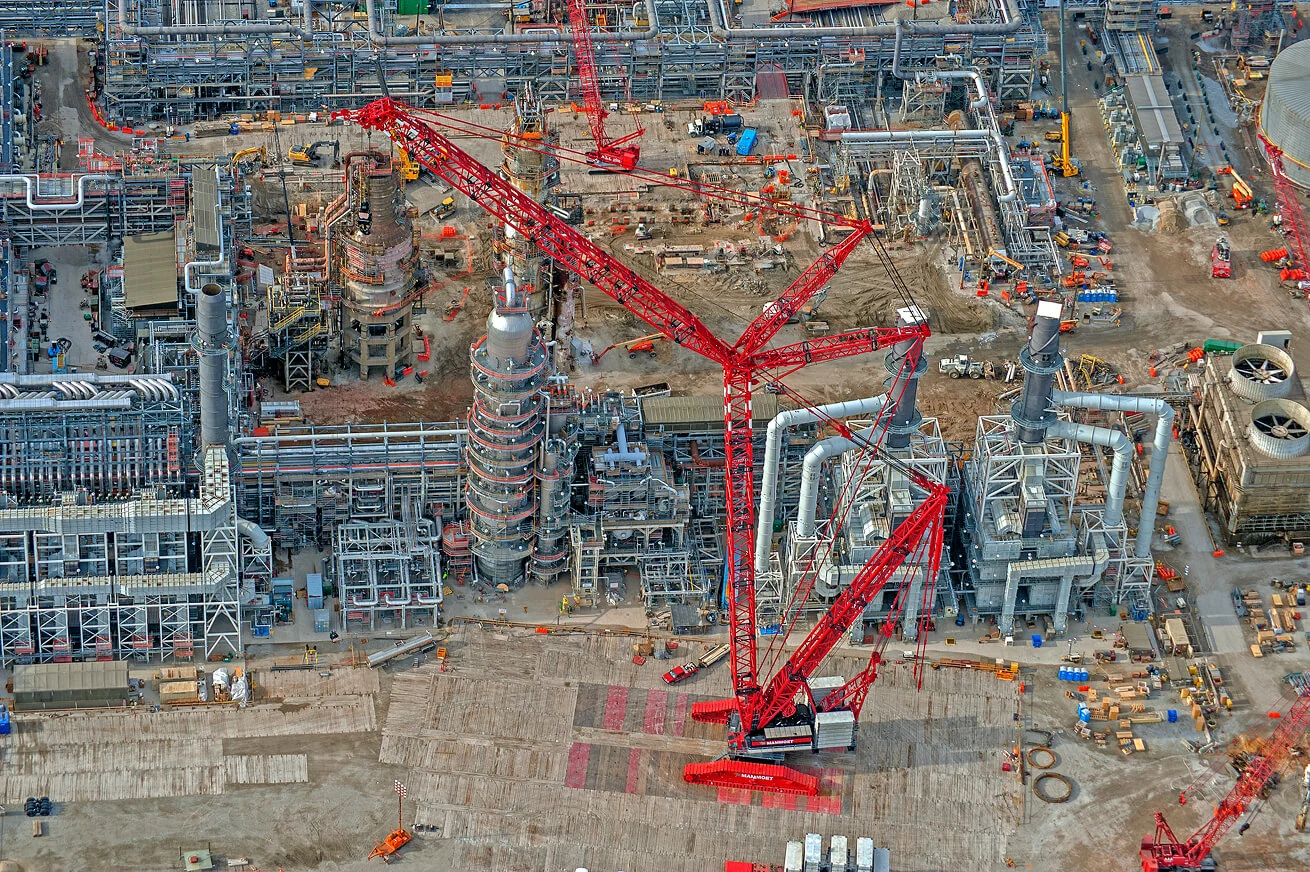

The initial turnaround plan included over 1.2 million craft hours for demolishing the existing crude unit, installing 29 pre-manufactured modules, and integrating this work with previously completed capital projects. Leveraging BMWC’s lean construction expertise, the integrated team eliminated 600,000 craft hours by performing this work offsite in a controlled environment. The team further enhanced efficiency by constructing super modules by combining and stacking multiple modules to create larger units that could be installed directly within the active refinery. Additionally, they developed an execution plan for 14 new modules for pump and exchanger alleys, incorporating equipment, steel, electrical, and piping systems. Pre-casting pump, exchanger, and equipment foundations allowed these components to be set in place during the outage, further optimizing the schedule.

The project’s success resulted from all contractors working together to achieve the same goal: a safe and on-time delivery of the turnaround. This collaborative approach ensured the project was completed on time and earned the Lean Construction Institute’s recognition for the effective implementation of lean practices throughout the project lifecycle.