Project Scope

BMWC, in partnership with Progressive Mechanical, successfully delivered the $600M mechanical scope of work for a greenfield, multi-billion-dollar EV battery manufacturing facility in Kokomo, IN. BMWC’s scope of work included the installation of critical utility and mechanical systems, such as chilled water, nitrogen, HVAC systems, solvent recovery, and industrial waste systems. BMWC began pre-construction activities in the fall of 2022, and substantial completion was delivered in the spring of 2025. The 30-month project totaled over 3M direct-hire craft hours and had a peak headcount of over 1,200 skilled crafts personnel.

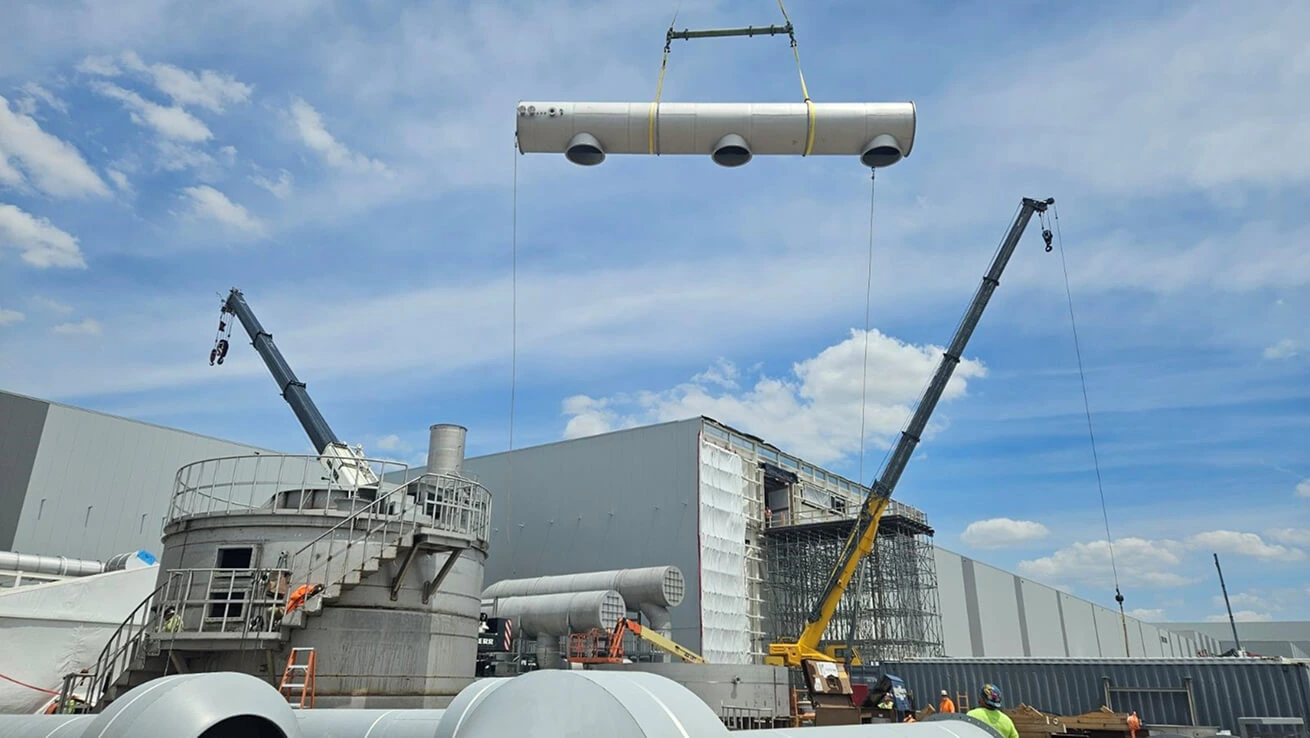

Innovation drove the success of this project. Over 1,200 pipe rack modules were fabricated offsite at BMWC’s fabrication facilities. Our Gary, IN, and Indianapolis, IN fabrication facilities fabricated piping spools, and our Lima, OH fabrication facility assembled the pipe rack modules. The completed pipe rack assemblies were shipped to a temporary, near-site storage facility for just-in-time delivery to the project site. Innovative software applications like Power BI and OpenSpace were utilized throughout the project, enabling our teams to deliver real-time tracking and live progress visualization to the Client. Additionally, BMWC’s in-house Virtual Design and Construction department deployed 40+ professionals, including detailers, surveyors, and other BIM professionals, to ensure precise coordination between the off-site fabrication and field installation teams.

Collaboration between BMWC, Progressive Mechanical, and subcontractor partners was crucial in achieving the project’s ambitious goals. By combining expertise, leveraging advanced technology, and focusing on safety and efficiency, this project became a prime example of how BMWC combines expertise, planning, innovation, and teamwork to deliver a large-scale industrial construction project.