Project Scope

BMWC Constructors partnered with a leading biopharmaceutical company to successfully deliver the plumbing, process, and utility piping scopes of work for their newest fill-finish operation in Concord, NC. These were BMWC’s sixth, seventh, and eighth pre-filled syringe lines installed for this longstanding client.

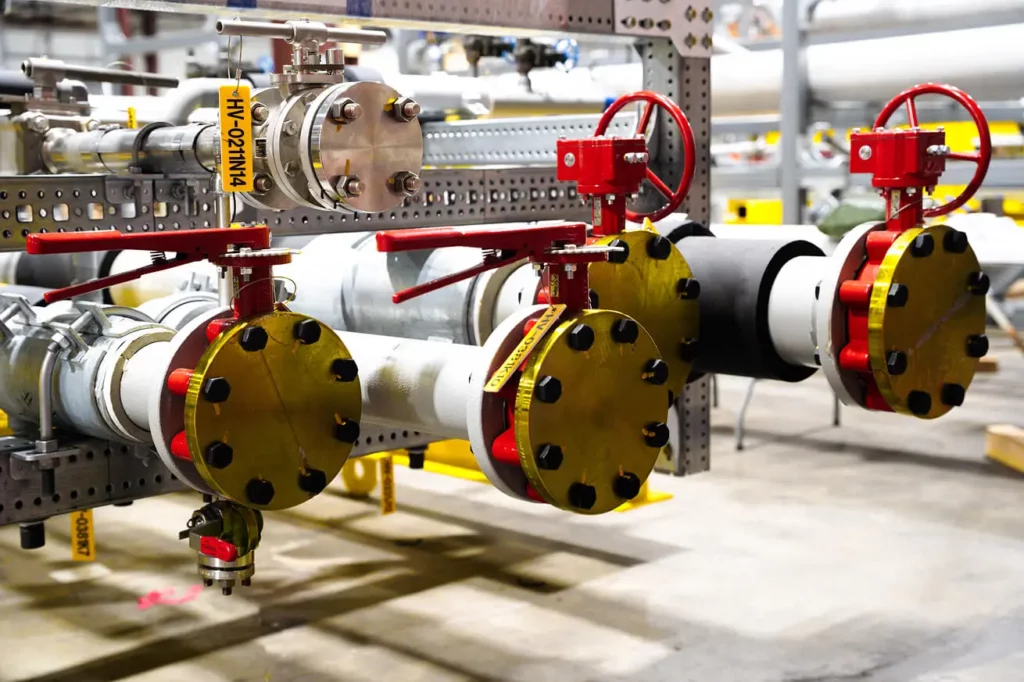

BMWC executed 330,000 direct-hire craft hours with zero injuries. To drive field productivity and mitigate labor resource constraints, BMWC developed a detailed off-site fabrication plan and executed most welds at their off-site fabrication facility. BMWC completed 30,300 welds, 15,200 of which were hygienic, and avoided rework delays by delivering a 0.45% weld reject rate. Time to market was critical for this client. BMWC developed an execution plan allowing the steam PRV stations, pumps, and exchangers to be assembled off-site, complete with piping and supports, and shipped to the project as a skid.

A critical aspect of the project was the tie-ins on several pieces of equipment, including working closely with the fill line equipment supplier.

BMWC completed tie-ins on the following pieces of equipment:

- Autoclaves

- Parts Washer

- 3 Fill Lines

- Inspection Stations

- WFI Still

- Clean Steam Generator

- Formulation Equipment

- Waste Neutralization System

Integrated project planning, a detailed off-site fabrication plan, model coordination throughout the project, exceptional quality performance, and zero injuries allowed BMWC to deliver the project on time and within budget.