Project Scope

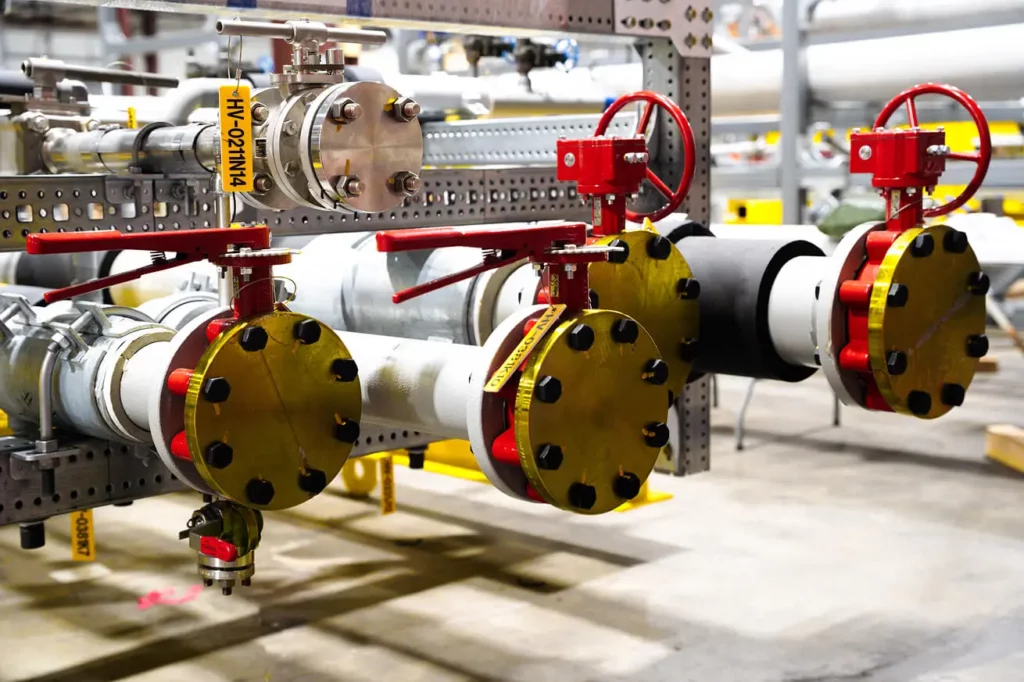

BMWC played an integral role in the construction of a multi-billion-dollar drug substance manufacturing campus in Holly Springs, NC. BMWC’s scope on the DSM 2 phase of the project included off-site fabrication and installation of 35,000 feet of hygienic piping. The project team’s focus on safety was a key element to the project’s success. In close collaboration with Jacobs, the project’s construction manager, BMWC executed 200,000 hours on-site and 35,000 hours in the fabrication shop injury-free. In addition to delivering the project safely, BMWC’s weld reject rate for on-site and fabrication shop welds was 0.04, reducing delays associated with re-work.

To drive field productivity and mitigate on-site labor resource risks, BMWC developed and executed a detailed off-site fabrication plan, executing most welds in one of BMWC’s off-site fabrication facilities. Seamless communication between the on-site project team and BMWC’s fabrication shop increased craft productivity through the just-in-time delivery of fabricated piping spools. BMWC’s fabrication team worked closely with the field execution team during preconstruction to develop work packages that led to an efficient installation process. The collaboration between BMWC, Jacobs, and the customer was essential in meeting the project’s demanding schedule.