Project Scope

BMWC partnered with a jet engine manufacturing client to modernize their World War II-era manufacturing facility. The upgraded facility enhanced the client’s ability to develop, engineer, and manufacture components for military and commercial applications. BMWC’s role in the expansion involved simultaneous work across three buildings, executed through multiple phases and schedules. This complex effort required meticulous management of priorities, schedules, equipment, and subcontractors to ensure clear communication and prevent project delays and interruption to the client’s ongoing operations.

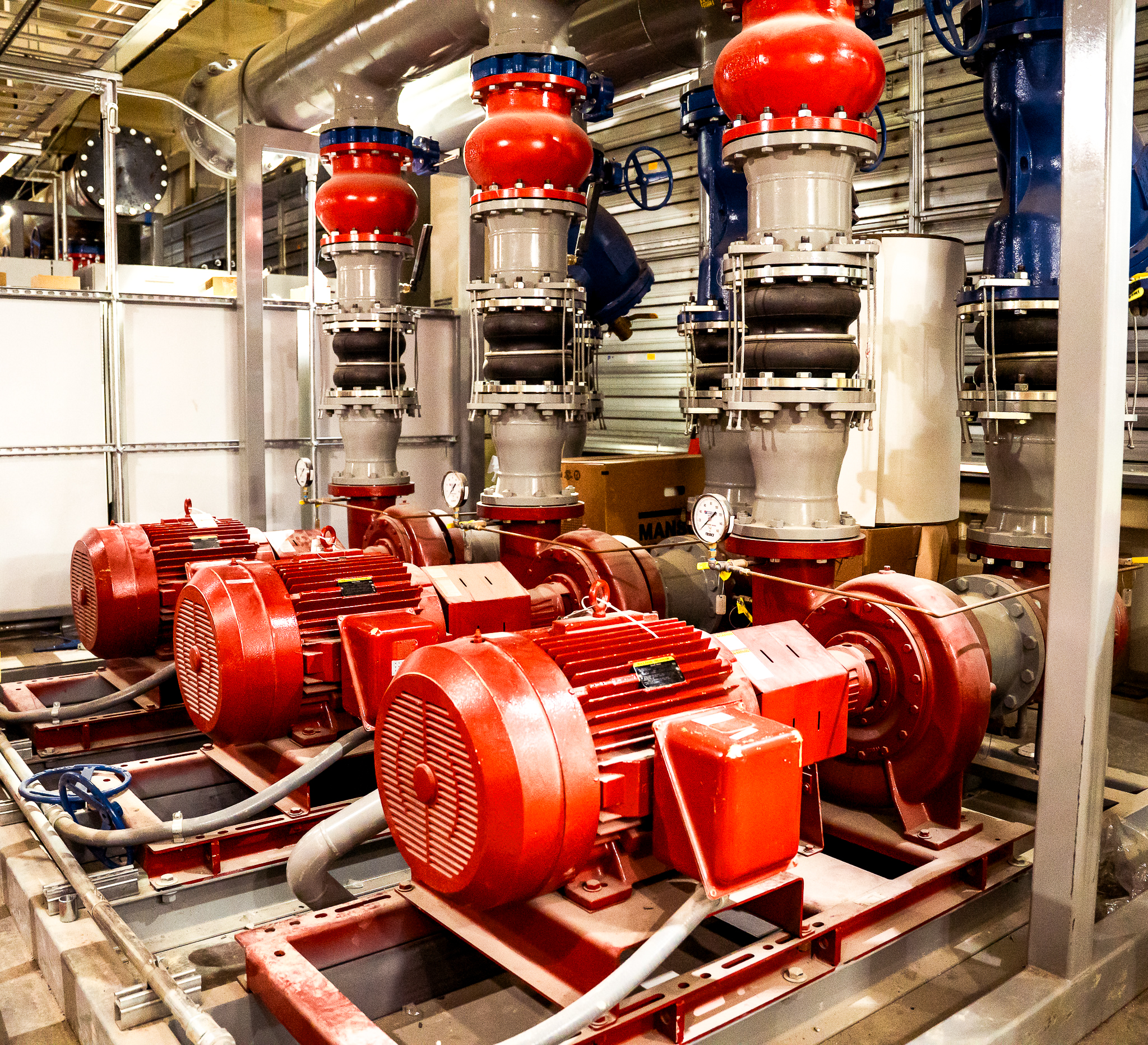

BMWC’s scope of work included installing new piping systems, including industrial waste, storm, sanitary, and domestic piping, throughout multiple buildings on the manufacturing campus. In addition to the piping scopes of work, BMWC installed 30 HVAC units throughout the campus, with condensers weighing up to 18,000 pounds.

A standout achievement for BMWC was identifying a safer, more cost-effective alternative for installing the new HVAC units. The original plan called for individual penthouses to house the units, a labor-intensive and logistically challenging approach. The BMWC team proposed placing the units on the roof instead, capitalizing on their design for outdoor use. This solution significantly reduced labor, minimized risk, and optimized the client’s internal footprint by transitioning the units to an external setup.

The multi-phased project was delivered on time despite an expanded work scope and executed with zero recordable injuries.