Project Scope

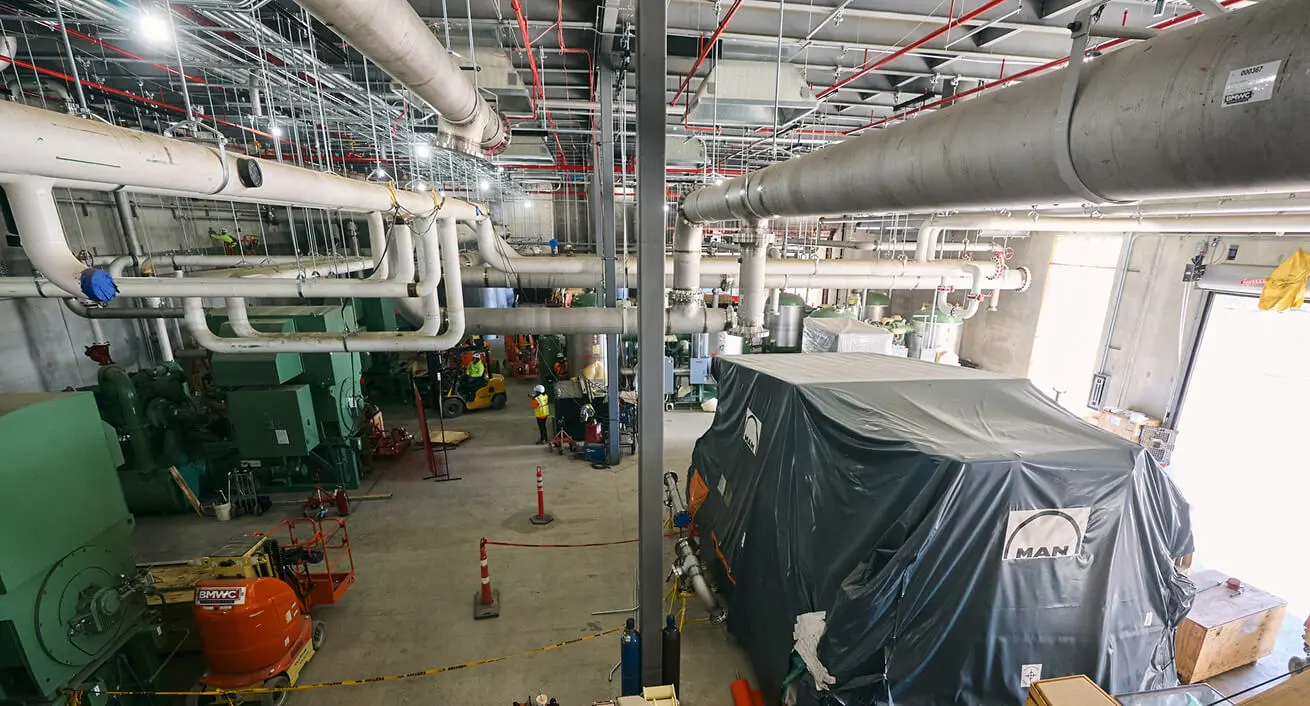

BMWC completed a complex piping and equipment installation project for a confidential aerospace client. The scope of work included procuring equipment, off-site fabrication of large bore piping, installing large pieces of equipment, and installing all piping systems essential to operating an air test facility.

BMWC procured, assembled, and installed air compressors, dryers, turbo expanders, 10,000 receiver tanks, and multiple heat exchangers. BMWC’s piping scope of work involved installing over 8,000 linear feet of stainless and carbon steel piping, the majority of which was 24” and larger in diameter. Successfully delivering the $50M project on time, within budget, and with zero recordable incidents demonstrated BMWC’s expertise in large-scale industrial installations.

To maintain transparency and provide real-time project updates with the client, the project team utilized OpenSpace technology to provide weekly 360-degree video updates, enhancing communication and allowing remote management team members from the client to stay updated on progress. BMWC’s project team utilized OpenSpace to measure field production by comparing the job walk data collected via OpenSpace to the model and BMWC’s labor plan.

Collaboration between BMWC and key subcontractors during equipment assembly and installation was crucial to keeping the project on schedule. This project reinforced BMWC’s position as a trusted partner in managing high-profile technical installations in the aerospace sector.